In the realm of industrial processes, the efficiency of heat transfer plays a pivotal role in optimizing various operations. Two key players in this domain are stainless steel heat exchangers and plate and frame heat exchangers. In this comprehensive exploration, we delve into the intricacies of these heat exchange technologies, understanding their design, applications, and the unparalleled benefits they offer to diverse industries.

Stainless Steel Heat Exchangers: A Corrosion-Resistant Marvel

Stainless steel heat exchangers stand as corrosion-resistant marvels, embodying durability and reliability. Leveraging the exceptional properties of stainless steel, these heat exchangers excel in applications where resistance to rust and corrosion is paramount. Their robust design ensures longevity, making them indispensable in diverse industries for seamless heat transfer.

Overview

Stainless steel heat exchangers have emerged as indispensable components in diverse industries due to their exceptional corrosion resistance and durability. These heat exchangers leverage the properties of stainless steel, a robust alloy known for its resistance to rust and corrosion, making it an ideal choice for applications that involve aggressive fluids or corrosive environments.

Design Features and Variations

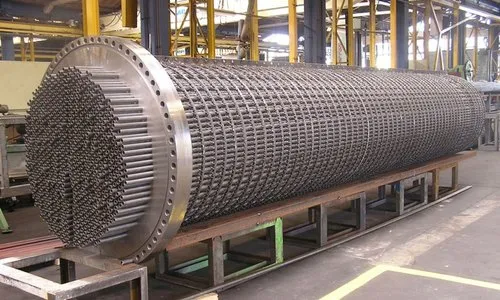

They come in various designs to cater to specific industry needs. Common variations include shell-and-tube, finned tube, and coil-type heat exchangers. Each design boasts unique characteristics, enabling their seamless integration into processes ranging from chemical manufacturing to HVAC systems.

Applications Across Industries

From chemical processing plants to food and beverage industries, stainless steel heat exchangers find applications in a myriad of settings. Their ability to withstand harsh conditions and maintain thermal efficiency makes them a preferred choice for processes where reliability and longevity are paramount.

Plate and Frame Heat Exchangers: Engineering Efficiency in a Compact Design

Plate and frame heat exchangers redefine efficiency with their innovative design, featuring a series of corrugated metal plates. Compact yet powerful, they optimize heat transfer in diverse applications. Their modular structure facilitates scalability, while the corrugations enhance fluid flow, making plate and frame exchangers an engineering marvel for space-conscious environments.

Unveiling the Plate and Frame Design

Plate and frame heat exchangers revolutionize heat transfer with their innovative design. Comprising a series of corrugated metal plates, these exchangers create a highly efficient heat transfer surface within a compact framework. The arrangement of plates allows for optimal fluid flow, maximizing heat exchange efficiency.

Advantages Over Traditional Designs

In comparison to traditional heat exchanger designs, plate and frame heat exchangers offer several advantages. Their compact size translates to a smaller footprint, making them ideal for space-constrained environments. Additionally, the modular design allows for easy scalability, providing flexibility to adapt to varying heat transfer requirements.

Diverse Applications and Industry Adaptation

Plate and frame heat exchangers have found widespread acceptance in industries such as pharmaceuticals, HVAC, and power generation. Their ability to handle high temperatures and pressures, coupled with ease of maintenance, positions them as a versatile solution across diverse applications.

The Synergy of Stainless Steel and Plate and Frame Design

The synergy of both represents a pinnacle of engineering excellence. This fusion combines the corrosion-resistant prowess of stainless steel with the compact efficiency of plate and frame technology, creating a robust and high-performance solution for industries demanding durability, thermal efficiency, and versatility.

Best of Both Worlds

When the durability of stainless steel meets the efficiency of plate and frame design, a powerful synergy is born. Both combine the corrosion-resistant properties of stainless steel with the compact and efficient design of plate and frame technology, resulting in a high-performance solution for demanding industrial processes.

Ideal Applications and Performance Metrics

Industries requiring both corrosion resistance and efficient heat transfer benefit significantly from stainless steel plate and frame heat exchangers. From petrochemical plants to renewable energy facilities, these hybrid exchangers excel in applications where fluid purity is essential, and thermal performance cannot be compromised.

Key Considerations in Selecting the Right Heat Exchanger

Here are some key considerations in selecting the right heat exchanger:

Assessing Operational Requirements

Choosing between both necessitates a thorough understanding of operational requirements. Factors such as fluid properties, temperature ranges, and space constraints must be carefully evaluated to determine the most suitable heat exchange solution.

Cost-Efficiency and Long-Term Benefits

While the initial investment is a crucial consideration, evaluating the long-term benefits is equally important. Stainless steel heat exchangers, with their corrosion resistance and durability, often prove to be cost-effective in the long run. Similarly, the compact design and efficiency of plate and frame exchangers contribute to lower operational costs over time.

Conclusion: Elevating Industrial Processes with Advanced Heat Exchange Solutions

In the dynamic landscape of industrial processes, the choice of heat exchanger technology significantly influences operational efficiency and long-term sustainability. Both stand out as exemplary solutions, each offering unique advantages. By understanding the intricacies of these technologies and their synergies, industries can make informed decisions, propelling them towards enhanced performance, reliability, and economic viability. As we embrace the future of industrial innovation, the marriage of stainless steel and plate and frame design emerges as a symbol of progress, ushering in a new era of efficiency and durability in heat exchange systems.