In the intricate world of machining, one process stands out for its precision and versatility—EDM hole drilling. This advanced method has become indispensable in various industries, offering unparalleled accuracy in creating holes of different sizes and shapes. In Minnesota, where precision engineering is a hallmark, EDM hole drilling has found a niche in the manufacturing landscape. Let’s delve into the fascinating process behind EDM hole drilling and explore its key components that contribute to its success.

Understanding EDM Hole Drilling

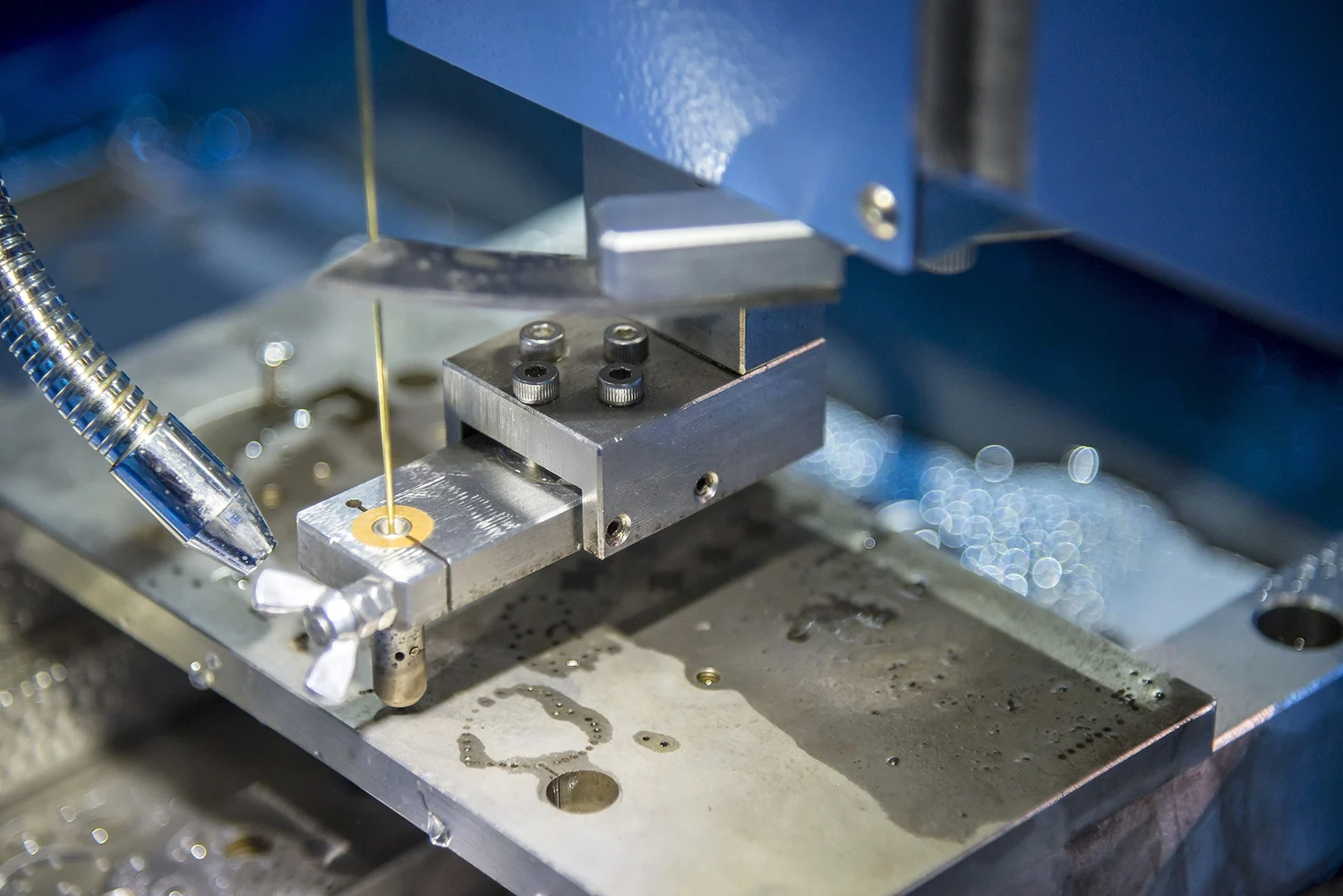

Electrical Discharge Machining (EDM) hole drilling is a non-traditional machining process that utilizes electrical discharges to erode material and create precise holes. The process involves a tool, typically made of brass or copper, and a workpiece submerged in a dielectric fluid. The tool, often referred to as an electrode, emits electrical discharges that erode the workpiece, leaving behind an accurate hole. This method is particularly advantageous when dealing with materials that are difficult to machine using traditional methods, such as hardened steel or exotic alloys.

Key Components of EDM Hole Drilling

- Electrode Material and Design

The choice of electrode material plays a crucial role in EDM hole drilling. Common materials include brass and copper due to their excellent electrical conductivity. The design of the electrode also influences the outcome, with various shapes and configurations tailored to specific applications. The electrode must be meticulously crafted to ensure optimal performance and longevity during the EDM process.

- Dielectric Fluid

The dielectric fluid is a vital component in the EDM hole drilling process. It serves multiple purposes, including flushing away eroded particles, preventing arcing between the electrode and workpiece, and maintaining a stable electrical discharge. Dielectric fluids must exhibit high insulating properties and be compatible with the materials being machined. In Minnesota’s machining industry, where precision is paramount, the choice of dielectric fluid is a critical consideration.

- Power Supply

The power supply is the driving force behind EDM hole drilling. It generates the electrical pulses that create controlled discharges between the electrode and the workpiece. The power supply’s parameters, such as pulse duration and frequency, can be adjusted to achieve the desired results. Precision in EDM drilling often hinges on the capabilities of the power supply, making it a key component in the process.

- Control System

An advanced control system is essential for achieving the level of precision required in EDM hole drilling. This system manages and regulates the electrical discharges, ensuring that the machining process adheres to the specified parameters. The control system also facilitates automation, allowing for the creation of complex patterns and intricate hole geometries with minimal operator intervention.

EDM Hole Drilling in Minnesota: Precision at Its Finest

Minnesota’s thriving manufacturing sector has embraced EDM hole drilling for its ability to deliver precision in the most demanding applications. Whether it’s aerospace components, medical devices, or intricate molds, EDM hole drilling has become a go-to method for achieving tight tolerances and complex features.

The skilled workforce in Minnesota understands the importance of investing in cutting-edge technology for EDM machining. As businesses seek reliable solutions for EDM hole drilling, one name stands out—Iron Machine Tool. With a reputation for excellence and a commitment to precision, Iron Machine Tool offers state-of-the-art EDM drilling services that cater to the diverse needs of Minnesota’s industries.

Why Choose Iron Machine Tool for EDM Hole Drilling?

- Expertise and Experience

Iron Machine Tool brings decades of expertise to the table. Their team of skilled professionals understands the intricacies of EDM hole drilling and is well-equipped to tackle even the most challenging projects.

- Cutting-Edge Technology

Staying ahead in the competitive world of machining requires staying abreast of technological advancements. Iron Machine Tool prides itself on utilizing the latest and most advanced EDM drilling technology to deliver superior results.

- Customized Solutions

Every project is unique, and Iron Machine Tool recognizes the importance of tailoring solutions to meet specific requirements. Whether it’s a prototype or a high-volume production run, their team works closely with clients to ensure optimal outcomes.